This spillage can be up to 80% of the cut material. In most dredging operations, spillage results in losing a significant part of the cut material.

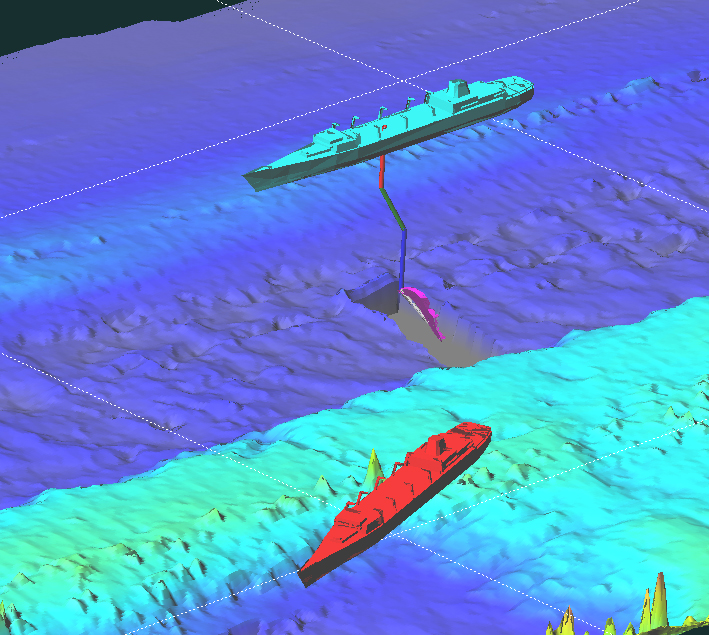

The prototype was assembled in Dredge Yard facility in Rotterdam and tested in dry conditions. To be able to do this, Dredge Yard developed and tested electric ring motors in collaboration with partners in Netherlands and Germany. Over years of intensive Engineering, FEM, and computer simulation Dredge Yard developed a cutter blade that will hold the cut material preventing them from falling down causing spillage and the blades are connected to the hub and suction pipe located in the center of the cutter ring motor. The new design of a closed type cutter head, driven by an electric ring motor offers a complete solution to environmentally friendly cutting. The prototype of a full-scale model is launched in Mid-January 2021 and ongoing testing to demonstrate the full potential of the new cutter.

With the aim to reduce spillage and turbidity in cutter suction dredging, Dredge Yard developed and tested a new Dredge Cutter System called DrillCutter.

0 kommentar(er)

0 kommentar(er)